Introduction to Sigma Mixers

In the vast world of industrial mixers, Sigma Mixers stand out for their efficiency, versatility, and reliability. These machines play a pivotal role in various sectors, including pharmaceuticals, food processing, chemicals, and more, by efficiently mixing a wide range of materials. This blog delves into seven must-know facts about Sigma Mixers, shedding light on their unique features, applications, and why they are an indispensable tool in numerous industrial processes.

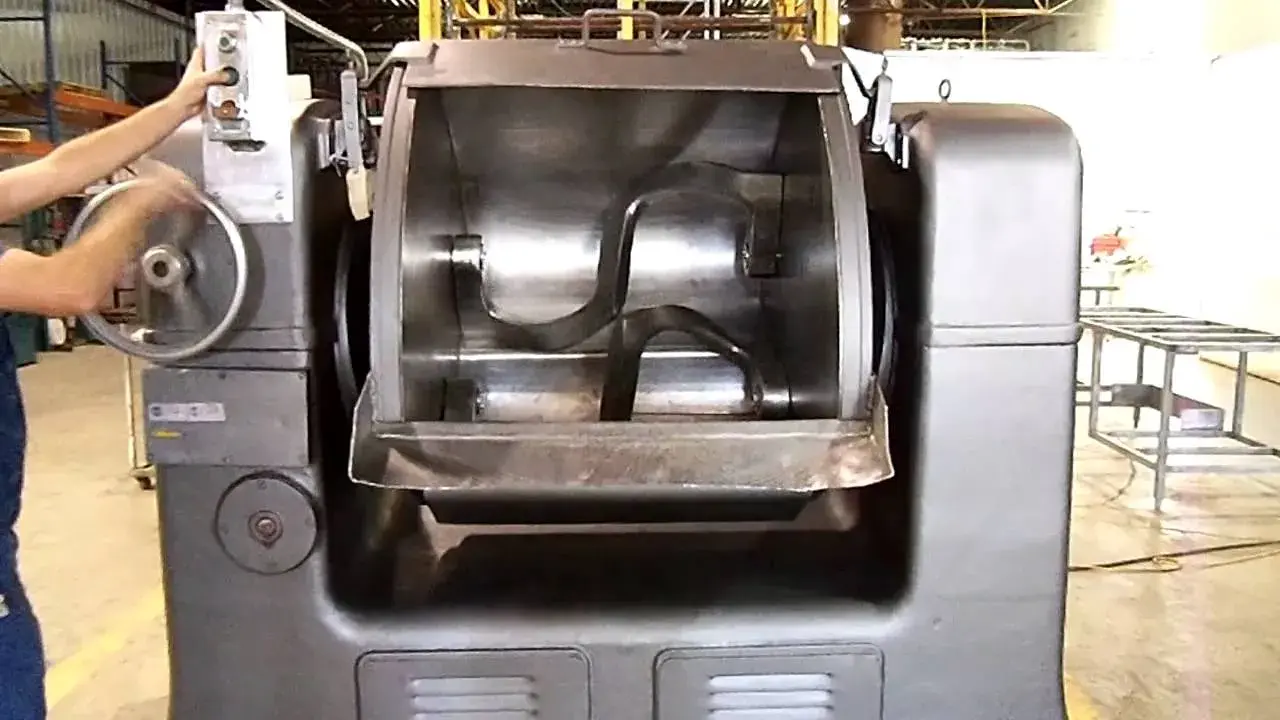

1. What are Sigma Mixers?

Sigma Mixers, characterized by their distinctive ‘Z’ shaped blades, are designed to facilitate thorough mixing of highly viscous materials. These mixers are equipped with two rotating blades that move at different speeds, ensuring uniform mixing. The design is not only efficient but also minimizes dead spots within the mixing chamber, guaranteeing a consistent blend of materials.

2. The Unique Design and Working Principle

The hallmark of Sigma Mixers is their unique design, which optimizes the mixing of viscous materials. The working principle revolves around the sigma-shaped blades that rotate toward each other at precisely controlled speeds. This action creates a shear force that kneads and mixes the materials, making it ideal for dough-like substances and other high-viscosity mixtures. The mixer’s design ensures that heat distribution is even, and the mixture remains uniform in texture and consistency.

3. Versatility in Application

Sigma Mixers are celebrated for their versatility, finding applications across a broad spectrum of industries. They are particularly prevalent in the food industry for dough and confectionery, the pharmaceutical industry for mixing medicinal compounds, and the chemical industry for various compounds. Their ability to handle different materials, from high-viscosity pastes to semi-solids, makes them invaluable in settings where precision and consistency are paramount.

4. Different Types of Sigma Mixers

Sigma Mixers come in various models, each tailored to specific industry needs. From laboratory size to large industrial scales, these mixers can handle capacities ranging from a few liters to several thousand. The models vary in terms of blade design, discharge mechanisms, and whether they are tilted or non-tilted, each feature designed to enhance mixing efficiency for specific material types and process requirements.

5. Key Benefits of Using Sigma Mixers

The advantages of using Sigma Mixers are manifold. They ensure uniform mixing of components, crucial in industries where product consistency is key. These mixers are also designed for easy loading and unloading of materials, reducing downtime and increasing productivity. Moreover, their robust construction and design mean that Sigma Mixers are durable, capable of withstanding the rigors of industrial use while requiring minimal maintenance.

6. Maintenance and Cleaning

Maintaining and cleaning Sigma Mixers is straightforward, ensuring they operate at peak efficiency. Regular maintenance checks are essential to identify wear and tear on components early on. Cleaning is made easier by features such as tilt-able mixing chambers and removable blades, allowing for thorough cleaning and ensuring compliance with industry standards for hygiene and cleanliness.

7. Recent Innovations and Technological Advancements

The world of Sigma Mixers is not static, with continuous innovations enhancing their functionality and efficiency. Technological advancements have led to the development of mixers with improved blade designs, more efficient motors, and sophisticated control systems that allow for precise adjustment of mixing parameters. These innovations ensure that Sigma Mixers can meet the evolving needs of industries, reinforcing their status as an essential tool in the industrial mixing process.

Conclusion

Sigma Mixers are a cornerstone of industrial mixing processes, valued for their efficiency, versatility, and reliability. Understanding these seven facts about Sigma Mixers illuminates their importance and why they remain a preferred choice across various sectors. Whether it’s the unique design, the wide range of applications, or the recent technological advancements, Sigma Mixers continue to play a critical role in achieving consistent and high-quality mixtures.